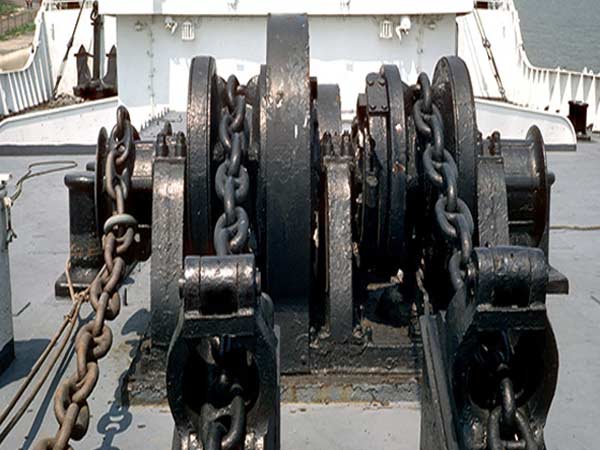

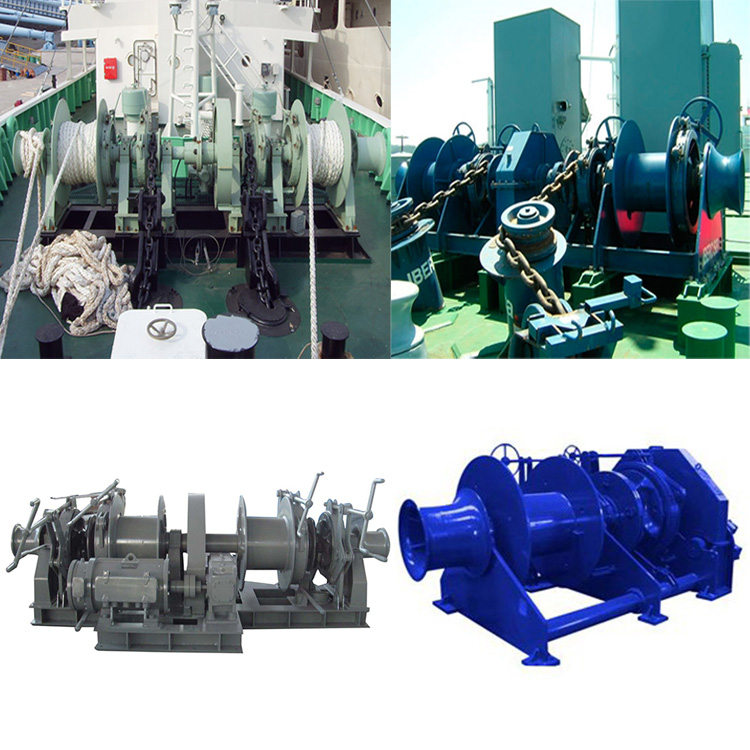

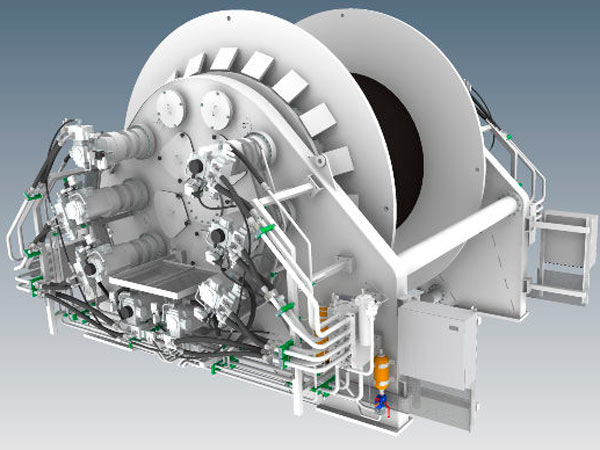

Ship winch refers to the winch mounted and used on a ship and it’s necessary deck equipment for the ship, which can be used for ship anchoring, mooring, towing and cargo lifting and cable pulling and so on. According to drum quantity, there are single drum ship winch, double drum ship winch and triple drum ship winch; the drum brake device should be able to withstand the winch support load, and it should not rotate after braking. According to drive type, ship winch includes electric ship winch, hydraulic ship winch, electric-hydraulic winch, diesel winch, steam winch and manual winch; according to the type of drums, the winch drums can be split or undivided as needed; as for the brake type and brake application, there are mainly band, disc, mechanical screw and spring applied. The main specifications of hydraulic winch consist of rated load, support load, rope speed, rope capacity, power mode etc.

Parameters of ship winch with two warping heads:

- Load capacity: 1 ton – 200 ton

- Drum capacity: 100m- 1500m

- Speed: 4.5m/min – 20 m/min

- No. of drum: single or double

- Drive type: electric, hydraulic or diesel

- Customized service provided

Double gypsy ship winch parameters:

- Load capacity: 1 ton – 100 ton

- Drum capacity: 100m- 1500m

- Speed: 4.5m/min – 20 m/min

- No. of gypsy: double

- Drive type: electric, hydraulic or diesel

- Customized service provided

Wide Applications of Ship Winch

A marine winch is a piece of marine deck equipment applied for handling ropes or wires, and works by spooling or winding the ropes or wires on a drum with a horizontal axis. Powered by electric or hydraulic motors, the winches on ship are fixed and used for various purposes.

Ship winches are very useful whenever the ships need to be anchored, stopped, towed or there are something on ships needed to be lifted or pulled. When a ship reaches a port or pier, it needs to stop, and the ship anchor and mooring winch will be used to help with the ship anchoring and mooring to make sure it stops and keeps in the place safely without moving or drifting; according to ships with different sizes, shapes and rope capacities, they will choose windlasses with different rated loads and drums; when the ship starts to set sail after the stop, the winch will let in the line attached to the anchor to make the ship leave the port or pier; when a ship needs to be towed under some special circumstances, the winch will connect the ship to the tug boat to implement the towing operations; when there are some loading and unloading operations on ship, the winch will also be used to finish the weights lifting work.

The most common use of winches on ships is for mooring, which means the winches are usually located on the fore and after the decks at both sides of the ships. The mooring system can hold a ship in position and prevents the ship from drifting away from a berth. The ship mooring winch performs variety of functions, for example, the winch serves to store the mooring line when it is not in use, and to haul the ship in place against environmental forces, or it can also act as a kind of safety device which releases the line load in a controlled way once the force in the mooring line increases to the limit of breakage.

Interested in our ship winches? or want the best prices?

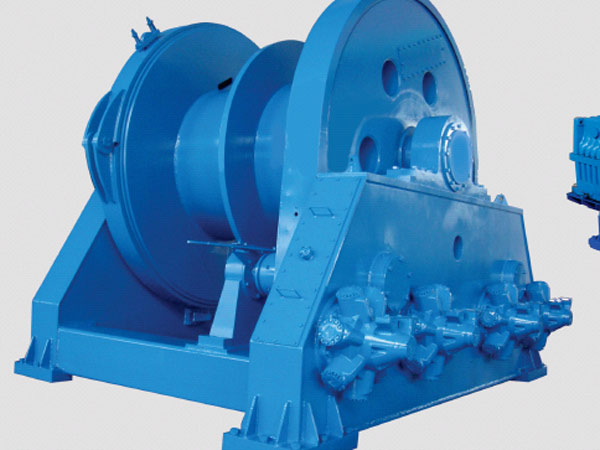

Electric and hydraulic ship winches are widely used on ships, electric winch gets its energy from a live current, and hydraulic winch relies on the pressured water chambers, which provides energy for it. Hydraulic winch is usually with large rated load and used on heavy ship. There are mainly five parts for a complete hydraulic system, and they are as follows:

(1) power device: it supplies the hydraulic system with pressure, converts the mechanical energy output from the motor to the pressure power of the oil and then drive the overall system to operate;

(2) actuator: it includes hydraulic cylinder and hydraulic motor; it is used to convert liquid pressure energy to mechanical energy to drive work parts operate;

(3) control and adjusting device: they consist of a variety of valves, such as pressure valve, flow valve and directional valve; they are used to control the liquid pressure, flow (flow rate), and the liquid flow direction of the hydraulic system, ensuring that the actuator finishes the expected work movement;

(4) auxiliary device: they include all kinds of pipe fittings, tubing, tank, filter, pressure gauge etc. They play role in connection, storage, filtration, storing pressure energy and measuring oil pressure to guarantee the reliable, stable and durable work of the hydraulic system;

(5) working medium: it refers to the oil bearing and transferring the pressure.

All in all, as a piece of necessary equipment on ship, the winch plays a very important role in the implementation of many operations, such as anchoring, towing, mooring, weights lifting on ship. With a high quality ship winch, those marine operations mentioned above can be ensured and the work efficiency can be greatly improved.

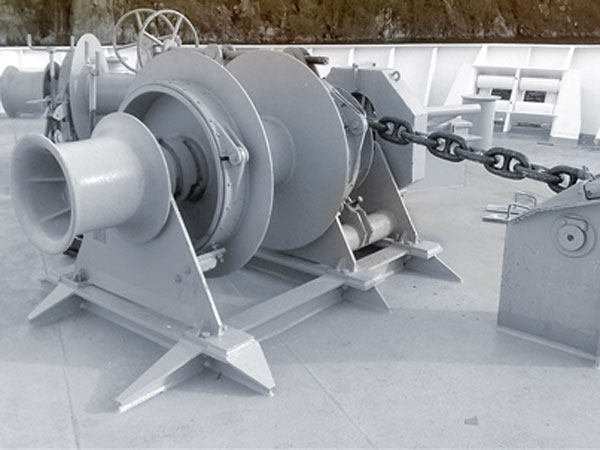

Ship anchor winch parameters:

- Load capacity: 1 ton – 100 ton

- Drum capacity: 100m- 1500m

- Speed: 5m/min – 20 m/min

- No. of drum/gypsy: single or double

- Drive type: electric, hydraulic or diesel

- Customized service provided

Ship mooring winch parameters:

- Load capacity: 1 ton – 200 ton

- Drum capacity: 200m- 1500m

- Speed: 5m/min – 20 m/min

- No. of drum: single or double

- Drive type: electric, hydraulic or diesel

- Customized service provided

Ship towing winch parameters:

- Load capacity: 1 ton – 300 ton

- Drum capacity: 100m- 2000m

- Speed: 4.5m/min – 20 m/min

- No. of drum: single or double

- Drive type: electric, hydraulic or diesel

- Customized service provided

Parameters of hydraulic ship winch for sale:

- Load capacity: 1 ton – 200 ton

- Drum capacity: 100m- 1500m

- Speed: 4.5m/min – 20 m/min

- No. of drum: single or double

- Drive type: hydraulic

- Customized service provided

If you need this kind of ship winch, please contact us because our company Sinma provides a wide range of winches for your choice, we produce single, double and triple drum winches with or without warping head, which can be powered by electric power, hydraulic pump, combination power of them, and diesel engine. The marine winches used on ship supplied by us are with high quality and work efficiency.

Choosing a Quality Ship Winch

When it comes to the choice of a winch for your ship, you will be faced with some questions and it will not be easy to make a final decision. There are many things you need to consider before you make the selection, and here are some tips for choosing a quality and suitable winch:

- It is vital to remember winch quality comes first. No matter what type of marine winch you want to buy, you must be sure that the quality of the winch is there, without good quality, and you purchase will not be a smart one.

- Know well about the work needs. For example, if you don’t know the working load of winch you need, you will not get a suitable winch for your ship.

- Make sure the marine winch supplier you choose is professional and reputable . You will not want to get a winch product from those who have little experience in winch business because you may end up with a low-quality winch.

- Do some research online and ask people for advice. Nowadays, it is convenient to get as much information as you need online, while you are going to buy a winch, it is important to do research to know more about the winch you need and to ask the people who have purchased and used the winch for some advice, you can also get some information on the winch from some professional staff.

- Always consider the winch price with care and just buy the suitable and affordable one to suit your work requirements.

Technical parameter

| Model | Chain Dia. | Working load | Supporting load | Working speed | Warping load | Warping speed | Motor power | Overall Dimensions | Weight |

| mm | KN | KN | m/min | m/min | KW | mm | T | ||

| El-24 | 24 | 25-27 | 149-214 | 9 | 20 | 8.5 | 8.5/3.5 | 1400x1625x1050 | 3.3 |

| El-26 | 26 | 29-32 | 175-250 | 9 | 20 | 8.5 | 8.5/3.5 | 1400x1625x1050 | 3.3 |

| El-28 | 28 | 33-37 | 202-289 | 9 | 20 | 8.5 | 11/11/7.5 | 1600x1845x1150 | 3.8 |

| El-30 | 30 | 38-42 | 231-331 | 9 | 30 | 8.5 | 11/11/7.5 | 1600x1845x1150 | 3.8 |

| El-32 | 32 | 44-49 | 262-375 | 9 | 30 | 8.5 | 16/16/11 | 1775x2025x1270 | 4.6 |

| El-34 | 34 | 49-55 | 295-422 | 9 | 30 | 8.5 | 16/16/11 | 1775x2025x1270 | 4.6 |

| El-36 | 36 | 55-62 | 329-473 | 9 | 30 | 8.5 | 16/16/11 | 1775x2025x1270 | 4.6 |

| El-38 | 38 | 61-69 | 365-522 | 9 | 50 | 8.5 | 22/22/16 | 1900x2150x1350 | 5.2 |

| El-40 | 40 | 68-76 | 403-576 | 9 | 50 | 8.5 | 22/22/16 | 1900x2150x1350 | 5.2 |

| El-42 | 42 | 75-84 | 442-630 | 9 | 50 | 8.5 | 22/22/16 | 1900x2150x1350 | 5.2 |

Technical Parameter

%0

| Model | Rated load | Rated speed | Rope capacity | Rope diameter | Motor power | Overall Dimensions |

| KN | m/min | m | mm | KW | mm | |

| YT1-16 | 160 | 7.5 | 500 | 28 | 45 | 3200x4050x2200 |

| YT1-20 | 200 | 7.5 | 500 | 30 | 55 | 3200x4050x2200 |

| YT1-25 | 250 | 7.5 | 550 | 32 | 75 | 3600x4350x2580 |

| YT1-32 | 320 | 7.5 | 600 | 36 | 90 | 3600x4500x2600 |

| YT1-40 | 400 | 5 | 750 | 40 | 90 | 3700x4800x2860 |

| YT1-50 | 500 | 5 | 750 | 52 | 110 | 3900x4900x3000 |

| YT1-63 | 630 | 5 | 850 | 54 | 110 | 4000x5100x3100 |

| YT1-80 | 800 | 5 | 1000 | 58 | 132 | 4250x5300x3300 |

| YT1-100 | 1000 | 5 | 1000 | 64 | 180 | 4550x5500x3450 |

| YT1-125 | 1250 | 5 | 1200 | 70 | 220 | 4850x5800x3700 |

| YT1-130 | 1300 | 5 | 1200 | 72 | 220 | 5000x6800x3800 |